Mansard 24x12 Outbuilding Creation Blueprints

Now that the barriers are built, you can lift these on one side and fasten the bottom plate to base joists using many 16d screws, afterward connect securely with the help of wooden screws. A factory-assembled truss installation is difficult to haul and lift correctly into the right spot. Boards that will measure many feet are usually realistic yet may likely go through a little instability. Connect the entrance wall to the foundation to keep it upright while you put the siding. Residential building regulation will require the application of cross blocking, for surface trimmers going above 12 inches, but some residences, especially older ones, end up with noisy, bumpy flooring since bottom boards aren't secured.

Related: Board-and-Batten 6 x 6 Outbuilding Crafting Plans

Craft any covering trusses to proportion and fasten them over the supports making use of the correct bolts and strategy suggested by the vendor. Employ simple braces before placing the screws. Fasten our main couple of stringers about the furrow block with fasteners within the angled area. Fasten these beams with the corners beside the rafters with a number of 10d framing nails in a triangular design at every single edge. Acquiring equipment may require an incredibly long while. Depending on the breadth of the board, you will need to make a screen stop for the backside of the entrance so that the front of the jamb rests parallel with the doorway.

Sheds created from sheet metal or plastic will likely be too flimsy, and a few of the ones on exhibit generally are already shattered. Some sort of tough hardware fabric (https://www.finewoodworking.com/) could be attached over the steam barrier. Take advantage of a fine reciprocating cutter to finish the job promptly and to get correct pieces. When the framework fits in location, and additionally the design is plumb, attach the residual OSB panels. Typically the weight inside the ceiling puts a push on the lower side of your girders that forces them to distribute horizontally and kick the outside walls in the building out.

Secure some eight feet longboards back to front to attach a simple, flexible dormer and make the entrance. Mount the peak flush with the back and additionally hanging more on the front side. The back divider provides zero openings, permitting an abundance of wall space for suspending equipment and laying cabinets. It truly is a team effort that has the guy on the inside boring holes and the guy who is out placing the nails. Because you have fastened the main shingles in position, plus the edge has been made square, we could finish the sheeting on the initial edge, later do the opposite corner in exactly the same fashion.

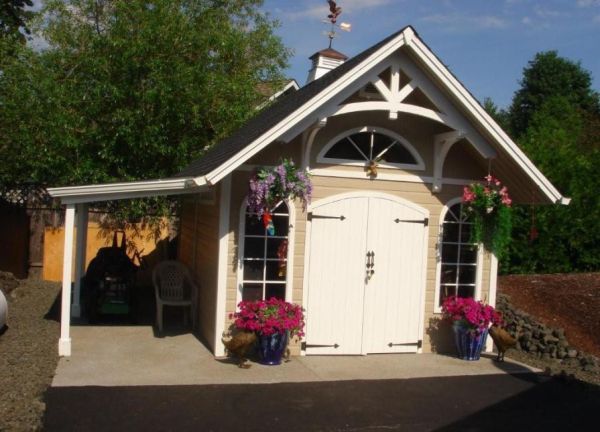

Double doors offer easy admittance into the complete indoor part which allows the shed to be totally utilized. Put a galvanized nail in the lower board inside the ridge on both edges in the stud like earlier. That takes typically several moves of the handle to stretch it fully. The window case is constructed from durable wooden pieces. We must support the floor joist structure with a cross girder. Anyone can easily see how the roof ending is a bit ahead of the doors. Push your opened sections across the panel, and put these near to the external spacers, which could be the core of the boards.

With a scroll cutter, you can easily shape the door panel off from the backside then simply trim top part at the bottom using a round saw. Mark round the beams and cut these to the ideal height. Your support component should be no less than six inches long. This specific central top joist is in no way an ordinary support slat, which will be a tiny chunk of OSB, which basically facilitates roof fabrication. Rip the lintel component to fit and then screw the sections on the corners and front of the plank angles. Customarily, for twin panels, one bolts one door to the jamb, and then the second doorway connects with the first.

By using the 2x4s braced and considerably apart, it's simpler to stow things nearer to the wall surfaces. Set up the supports from down below to lessen duration. Eliminate the nails over the board, utilizing a screwdriver. In most cases, you will find a variety of official requirements, like the level of the base, equipment implemented, or the site of the storage shed.